Purchase Your Workflows: Unlock Potential with Stacking Conveyors for Sale

Purchase Your Workflows: Unlock Potential with Stacking Conveyors for Sale

Blog Article

Boost Recycling Performance With Piling Conveyors: a Total Devices Overview

Advantages of Piling Conveyors in Recycling

Stacking conveyors provide numerous benefits in the recycling industry, improving effectiveness and lowering labor expenses. Among the vital advantages of using stacking conveyors in recycling is their capacity to increase throughput. These conveyors are developed to deal with large amounts of products, permitting a constant circulation of recyclables throughout the sorting process. By removing the requirement for hands-on handling and transportation of products, piling conveyors simplify the recycling process, decreasing downtime and increasing productivity.

One more benefit of piling conveyors is their adaptability. These conveyors can be customized to fit the specific demands of a recycling center, whether it be a large-scale center or a small operation.

Furthermore, stacking conveyors add to a more secure working atmosphere. By automating the motion and handling of products, they reduce the risk of manual labor-related injuries and accidents. This not just shields the health of employees yet additionally reduces the prospective expenses related to workplace injuries.

Types of Stacking Conveyors for Recycling

One crucial factor to consider when applying piling conveyors in a reusing center is the choice of the suitable sort of conveyor for the details needs of the procedure. There are numerous types of stacking conveyors that are typically made use of in reusing facilities, each with its own special features and benefits.

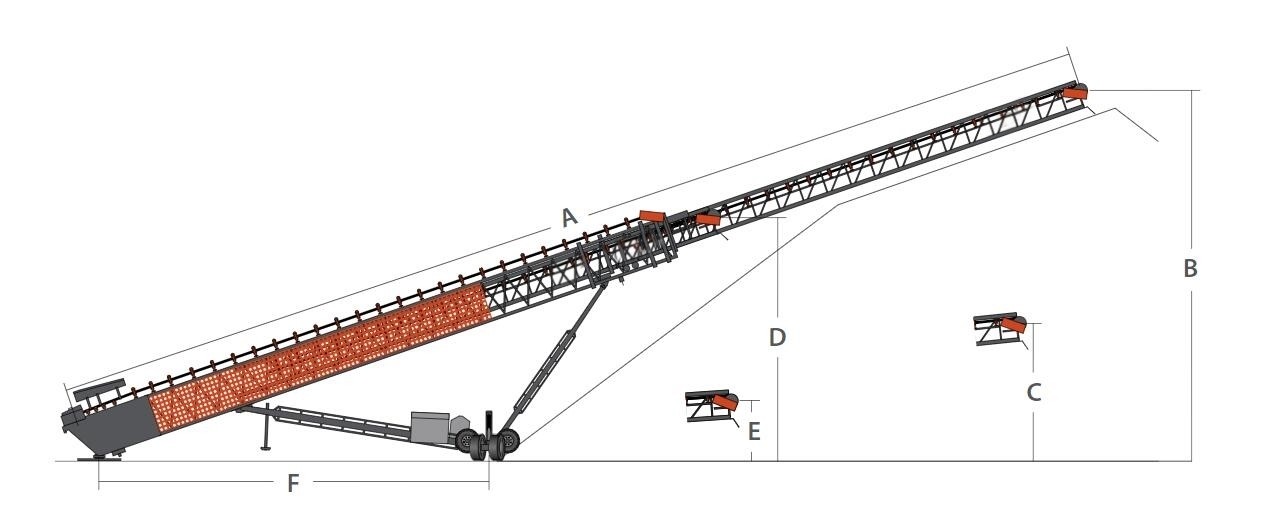

The first kind is the radial stacking conveyor, which is created to rotate around a central pivot point. This allows for higher versatility in regards to stockpiling materials, as the conveyor can be adjusted to produce a radial accumulation in any type of direction.

One more type is the telescoping conveyor, which can be prolonged or retracted to reach different sizes. This is particularly helpful in recycling centers where area is restricted, as the conveyor can be adjusted to fit within the offered location.

In addition, there are also fixed-length stacking conveyors, which are made to have a certain length and can not be changed - stacking conveyors for sale. These conveyors are frequently made use of in applications where a consistent stockpile dimension is called for

Lastly, there are tracked piling conveyors, which are mounted on tracks or wheels. This permits for very easy movement and positioning of the conveyor, making it suitable for reusing facilities that call for frequent relocation of devices.

Variables to Think About When Selecting a Piling Conveyor

When picking a piling conveyor for a recycling facility, it is necessary to carefully think about different factors to guarantee ideal efficiency and effectiveness. Among the crucial variables to consider is the type of material being taken care of. Various materials have her comment is here various qualities such as shape, size, and weight, which can influence the option of piling conveyor. If the center offers with heavy products such as metals or accumulations, a long lasting and robust stacking conveyor with a high lots capacity would be essential.

An additional important factor to consider is the necessary stacking height. The piling conveyor should have the ability to reach the desired elevation without compromising security or safety. Furthermore, the length and width of the stacking conveyor should be suitable for the readily available room in the center. stacking conveyors for sale. It is critical to make certain that the conveyor can be conveniently navigated and positioned within the center.

The speed and capacity of the piling conveyor are also important considerations. The conveyor must be able to manage the required quantity of product effectively, without creating any jams or disturbances in the recycling procedure. Moreover, the conveyor must have adjustable rate settings to fit various handling requirements.

Lastly, the longevity and maintenance requirements of the piling conveyor needs to be thought additional info about. It is suggested to choose a conveyor that is made from top notch materials and is made for sturdy usage. Additionally, simple maintenance and access to extra parts are very important elements to consider to minimize downtime and keep the reusing center running efficiently.

Installment and Upkeep Tips for Stacking Conveyors

To ensure optimal efficiency and long life of piling conveyors in a recycling facility, correct installment and upkeep are vital elements of their successful operation. When it concerns installment, it is crucial to adhere to the supplier's guidelines and recommendations. This consists of guaranteeing that the conveyors are firmly anchored to the ground to stop any motion or instability during procedure. In addition, proper placement of the conveyors is necessary to make certain smooth material transfer and stop any prospective damages to the tools.

Normal maintenance is additionally crucial to keep piling conveyors running effectively. It is also vital to keep the conveyors free and tidy from any type of particles or contaminants that might conflict with their operation.

Furthermore, having a positive upkeep schedule, including routine maintenance and replacing worn-out elements, is vital to prevent unforeseen failures and minimize downtime. Training personnel on appropriate procedure and upkeep treatments is equally crucial to guarantee risk-free and reliable handling of the devices.

Making Best Use Of Efficiency With Stacking Conveyors in Recycling

Piling conveyors play a crucial duty in maximizing effectiveness within reusing facilities. These powerful devices are developed to deliver and pile different materials, such as recyclable waste, in an arranged and reliable way. By utilizing stacking conveyors in recycling procedures, facilities can streamline their procedures, enhance productivity, and reduce labor costs.

One of the key benefits of stacking conveyors is their capability to create Bonuses accumulations of various materials. This removes the need for hand-operated sorting and storage space, as the conveyors can automatically transfer the materials in designated areas. This not just saves time however additionally lessens the danger of contamination or damages to the recyclable materials.

Stacking conveyors additionally contribute to a much safer working environment. By automating the motion and stacking of materials, employees are much less exposed to prospective threats, such as hefty lifting or slipping. This not only minimizes the threat of accidents however likewise enhances total efficiency by permitting employees to focus on various other tasks.

Verdict

Finally, stacking conveyors play a crucial role in boosting reusing performance. With their capability to efficiently move materials and their flexibility in taking care of different sorts of recyclables, piling conveyors are an useful asset in the recycling market. By considering variables such as conveyor upkeep, installment, and kind, recycling centers can make best use of the efficiency and efficiency of their procedures. Piling conveyors offer an effective service for boosting reusing procedures and advertising sustainability.

When choosing a stacking conveyor for a recycling center, it is necessary to meticulously take into consideration different variables to make certain optimum performance and efficiency.To make certain ideal performance and long life of stacking conveyors in a reusing facility, correct installment and maintenance are essential elements of their successful procedure.Stacking conveyors play a vital role in optimizing efficiency within reusing facilities. By using piling conveyors in recycling operations, centers can improve their procedures, improve productivity, and decrease labor prices.

With their ability to effectively move products and their adaptability in handling various kinds of recyclables, piling conveyors are a valuable asset in the recycling market.

Report this page